[News from the News Center]Recently, the team led by Academician Tian Yongjun from t State Key Laboratory of Meta-stable Materials Science and Technology of Yanshan University and the team led by Academician Yang Wei from the Cross Mechanics Center of Zhejiang University cooperated and had achieved ultra-high elastic strain (tensile strength) and room-temperature dislocation plasticity of diamond. Research results have been published in Nature And Cell.

Diamond is the hardest crystalline material, with extremely high strength, widely tunable band gap, and controllable nitrogen-vacancy center. Such properties of this unique material find a vast range of applications in high-pressure science, machinery-based industry, electronics and photonics devices, and even biomedicine. However, diamond is also the most brittle material due to the strongest C-C covalent bonds, and the measured elastic strain is less than 2%. As a result, diamond displays virtually no plasticity at room temperature and its brittle nature sets severe limitations in many applications.

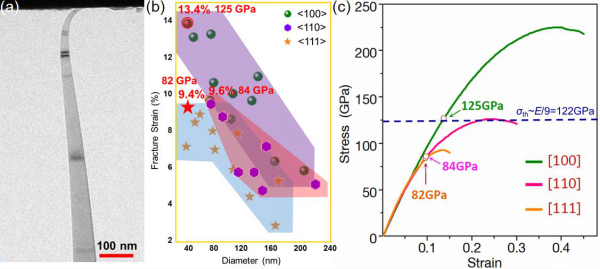

The two teams of Yanshan University and Zhejiang University cooperated to carry out in-situ bending experiments on diamond nanoneedles under the transmission electron microscope with the self-developed in-situ micro-nanomechanics experimental platform. The results show that maximum achievable elastic strain and strength are primarily determined by surface conditions of the nanoneedles, and reversible elastic deformation depends both on nanoneedle diameter and orientation.<100>-oriented nanoneedles with a diameter of 60 nm exhibit highest elastic tensile strain (13.4%) and tensile strength (125 GPa). These values are comparable with the theoretical elasticity and Griffith strength limits of diamond. This is the maximum achievable elastic strain and strength obtained by experiment so far. Such a large elastic strain can adjust the band gap of diamond in a wide range, which will further promote the application of diamond as a new generation of ideal semiconductor materials in flexible optoelectronic devices, biosensors and nanomechanical manipulators. The research is available on line on December 2019 by Nature Communications, link:

https://www.nature.com/articles/s41467-019-13378-w.

Diamond Nanoneedle In-situ Bending Measurement

(a) image of a diamond nanoneedle TEM scanning (b) Relationship between size and fracture strain of the nanoneedles (c) Theoretical stress-strain relation of uniaxial tension along [100], [110], and [111] directions for a bulk diamond

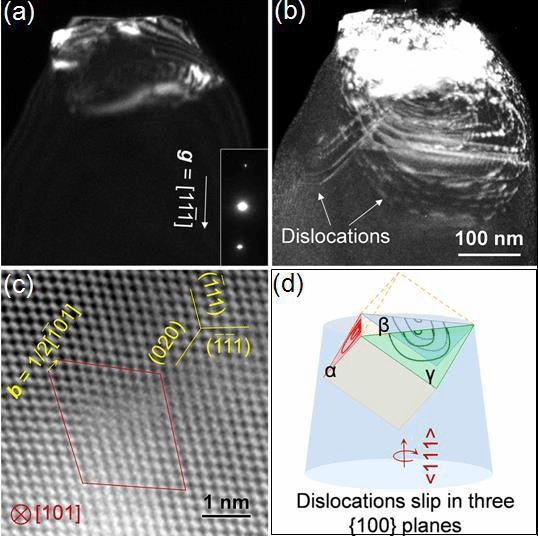

Subsequently, the two teams performed in situ TEM mechanical tests at room temperature on submicrometer-sized diamond pillars under the transmission electron microscope. Some unprecedented details are captured and documented as the spatiotemporal features of the dislocations introduced by the confinement-free compression, including dislocation generation and propagation. The preparation of pillars with<110>and<100>orientations follows the same procedure. A layer of amorphous carbon was present over the as-prepared pillars due to FIB milling. The cylindrical axis of the pillar was along the<111>direction, as confirmed by selected-area electron diffraction. A high-angle annular dark-field scanning TEM image shows nearly perfect atomic arrangements in the diamond pillar prior to the test.The research is available on line onMarch 10, 2020byMatter, link:https://www.cell.com/matter/fulltext/S2590-2385(20)30073-4.

(a) Weak-beam dark-field (DF) TEM image of a fractured diamond pillar (b) Dislocation half-loops propagated and multiplied. (c) Atomically resolved HAADF-STEM image showing a dislocation core after in situ deformation (d) Dislocation slip in three {100} planes

These results provide new insights into the mechanical behavior of diamond and stimulate reconsideration of the basic deformation mechanism in diamond as well as in other brittle covalent crystals at low temperatures.

The first author of the two research is Professor Nie Anmin, the first Affiliations is Yanshan University. The workwassupported by the National Key R&D Program of China (2018YFA0703400) and the National Natural Science Foundation of China (11725210, 11702165, 11672355, and 51672239).

[Translated by Yu Miao]