Professor Wen Bin and Researcher Zhang Liqiang from the State Key Laboratory of Metastable Materials Science and Technology at YSU, in collaboration with the team led by Professor Lu Yang from The University of Hong Kong, successfully developed an electron-beam-assisted cold welding technique for nanoscale amorphous silica (silica glass). The related achievements have been published in the journal Matter under the title Nanoscale cold welding of glass. Link: https://doi.org/10.1016/j.matt.2024.09.004.

This technique enables the direct fusion of silica nanospheres at room temperature. The strength, composition, and structure of the as-welded junctions appear the same as those of the pristine silica, while the diameter remains the same or becomes smaller compared with the pristine silica nanosphere. This method also allows the assembly of silica nanostructures of different shapes, with ultimate resolution subject to the nanoparticle size only. This approach would potentially allow ultra-high-resolution 3D printing, which offers a new approach for high precision additive manufacturing of nanoscale glass devices.

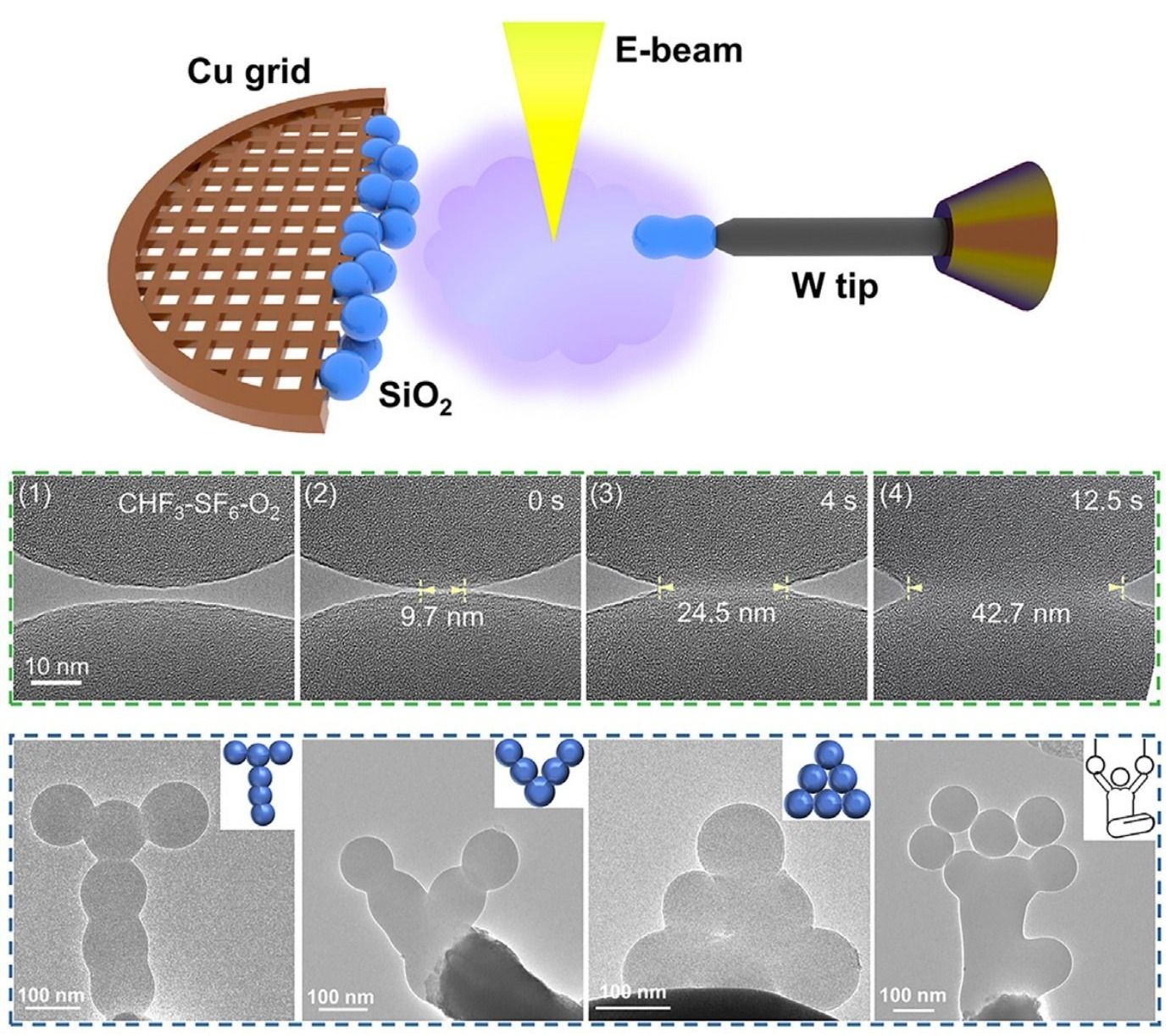

Figure 1 Diagram of cold welding of silica glass, the welding process, and the cold welding and bottom-up assembly of complex structured silica nanospheres

Figure 1 Diagram of cold welding of silica glass, the welding process, and the cold welding and bottom-up assembly of complex structured silica nanospheres

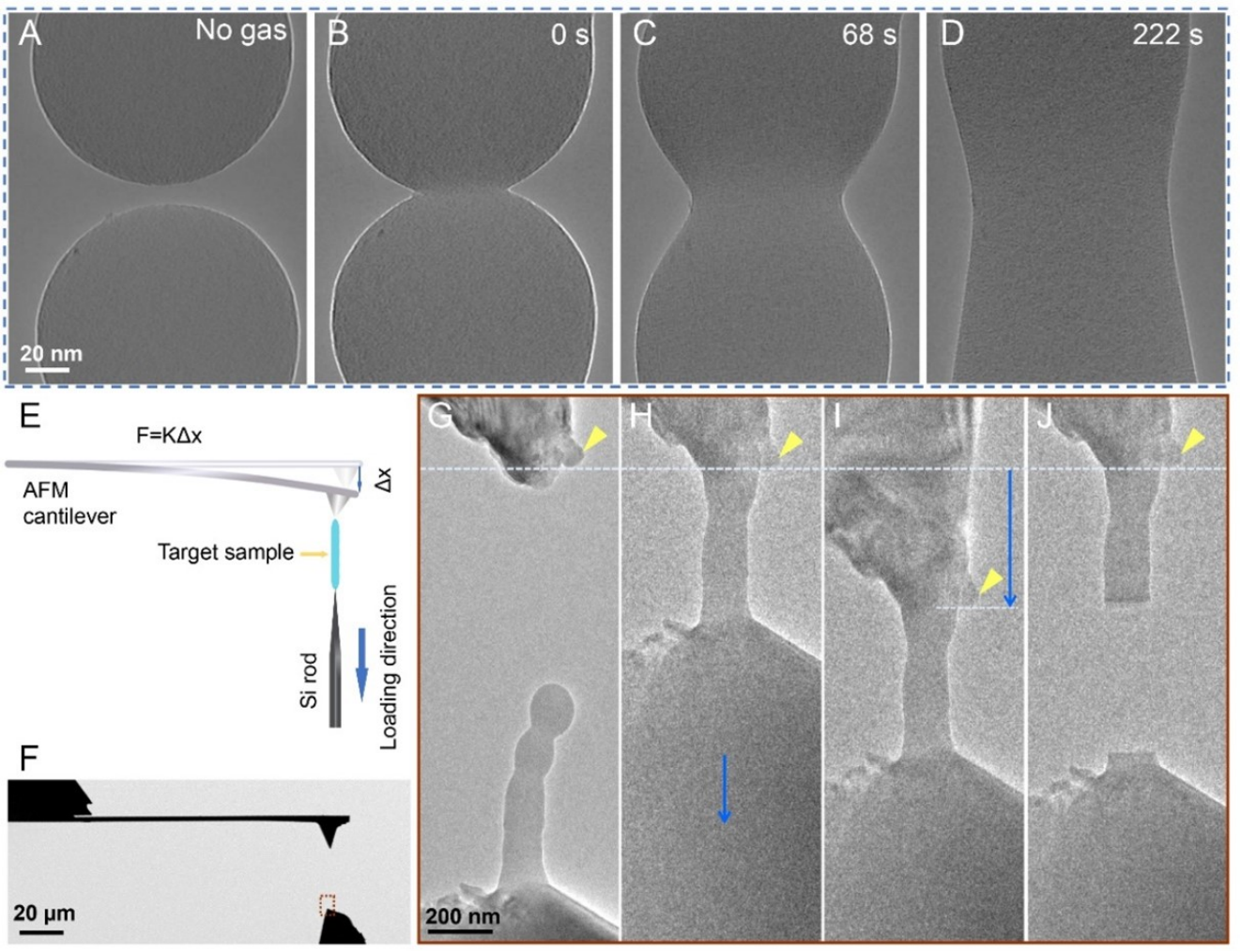

Figure 2 Interface formation of welding points, and tensile mechanical properties test

Figure 2 Interface formation of welding points, and tensile mechanical properties test

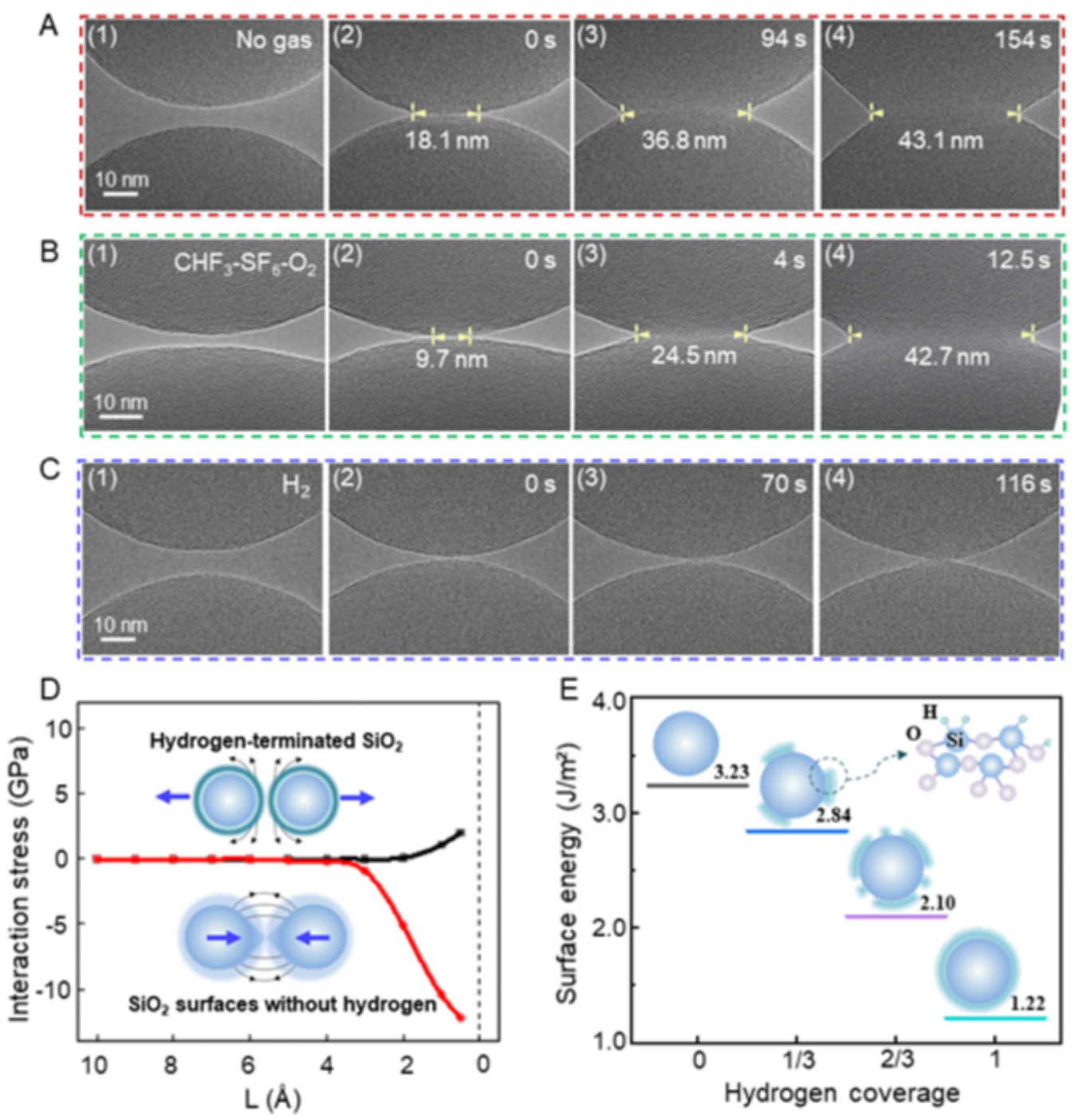

Figure 3 Research of the influence mechanism of atmosphere on welding speed

Figure 3 Research of the influence mechanism of atmosphere on welding speed

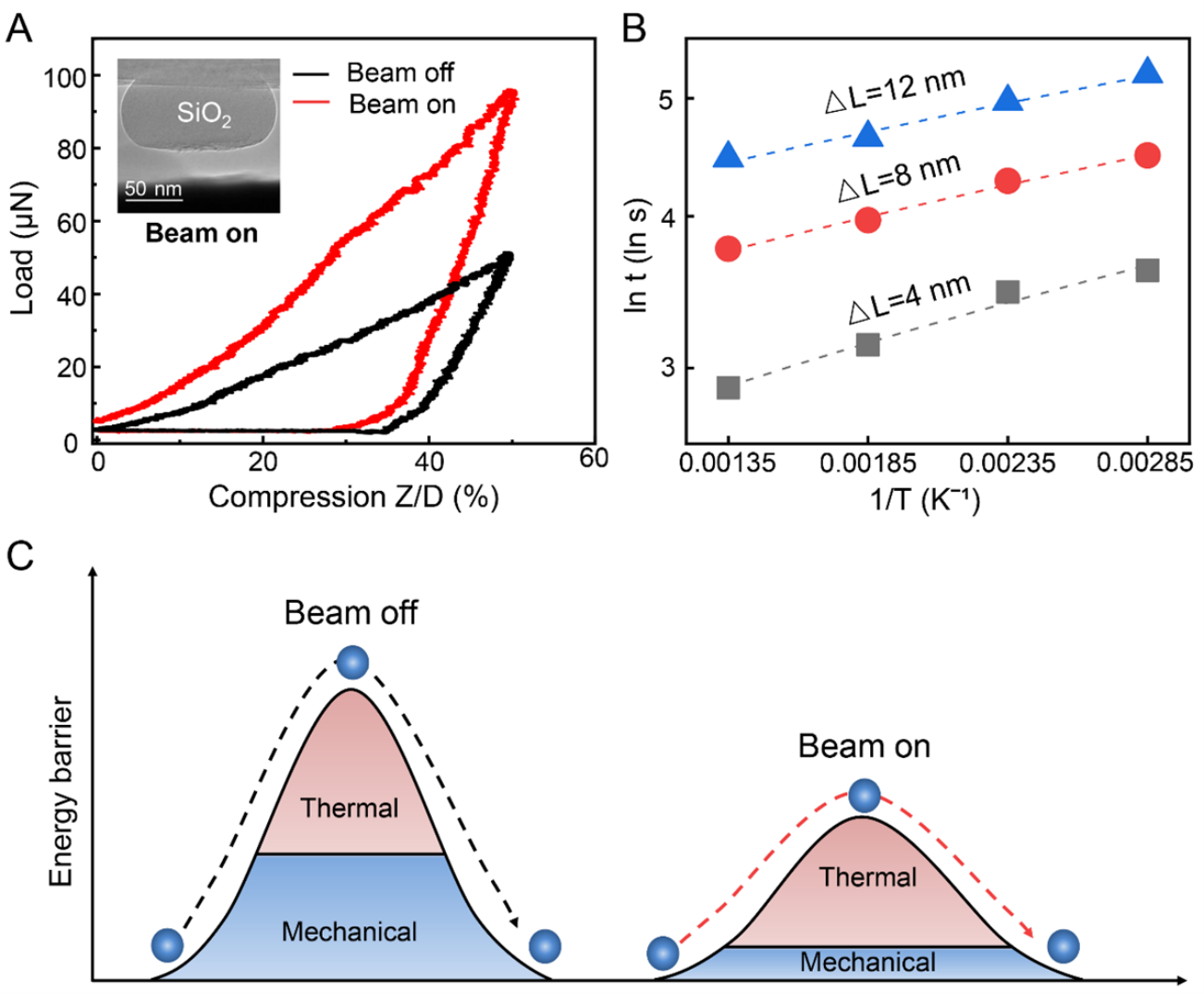

Figure 4 Diagram of thermal activation and force activation mechanism of cold welding process of silica nanospheres

Figure 4 Diagram of thermal activation and force activation mechanism of cold welding process of silica nanospheres

With excellent optical transparency, thermal stability, chemical stability and good mechanical properties, amorphous silica (silica glass) is an important material in modern engineering applications (micro-optics, nanofluidics, nanophotonics and nano-electromechanical system, etc.). The progress of industry places increasing requirements on the processing resolution of nanoscale glass. Despite various glass processing techniques such as 2D mask lithography, thermal oxidation, 3D lithography, direct ink writing and digital light processing, it is still challenging to achieve sub-200 nm precision. It’s mainly because these techniques rely on the fusion of precursors, which inevitably leads to severe silica agglomeration, greatly reducing the welding resolution. To date, high-resolution welding of nanoscale glass has remained a major challenge.

In order to improve the welding resolution for nanoscale glass, the research group proposed an electron-beam-assisted cold welding technique for nanoscale silica. In general, silica glass is brittle at room temperature, while becomes ductile only at high temperatures. However, it is found that with electron beam irradiation, silica glass would become quite ductile even at room temperature. On this basis, the research group achieved rapid cold welding of silica nanospheres at room temperature through electron beam irradiation and regulation of ambient atmosphere in a spherical aberration corrected Environmental Transmission Electron Microscopy (ETEM). This enables the direct and rapid fusion of silica nanospheres at room temperature. The the strength, composition, and structure of the as-welded junctions appear the same as those of the pristine silica, while the diameter is comparable with that of the pristine silica nanosphere. In addition, this technique allows the research group to achieve cold welding and bottom-up assembly of various complex structured silica nanospheres, while keeping an ultra-high welding resolution. The corresponding authors of the paper are Wen Bin, Lu Yang, and Zhang Liqiang; the first authors are Guo Yunna and Cui Hantao.