A research team led by Academician Tian Yongjun from YSU’s State Key Laboratory of Metastable Materials Science and Technology, in collaboration with researchers from Nanjing University of Science & Technology and Ningbo University, has recently achieved a significant breakthrough in the field of superhard materials. The team successfully synthesized an ultrafine nanotwinned diamond bulk material with a hardness of 276 GPa, setting a new world record for material hardness. The findings were published online in Nature Synthesis on January 3, 2025, under the title “Enhancing the Hardness of Diamond through Twin Refinement and Interlocked Twins”. The paper can be accessed via the following link: https://doi.org/10.1038/s44160-024-00707-1.

Diamond, known as the hardest material in nature, has a wide range of applications in mechanical processing, oil and gas exploration, and geological surveying. The hardness of single-crystal diamond varies with crystal orientation, ranging between 60–120 GPa. For a long time, researchers have been exploring methods to synthesize diamond materials with enhanced hardness. Grain refinement, a conventional approach to enhancing diamond hardness, has encountered a significant challenge at the nanoscale: the excessively high grain boundary energy tends to promote grain growth, hindering further refinement and thus limiting the potential for hardness enhancement.

To overcome this challenge, Academician Tian’s team pioneered a novel approach using twin refinement. Twin grain boundaries exhibit lower interfacial energy compared to traditional grain boundaries, opening up new possibilities for the ultra-refinement of materials. Previous research by the team has already demonstrated the feasibility of this method—they successfully synthesized a diamond bulk material with an average twin thickness of just 5 nm, achieving a hardness of 200 GPa, which is twice that of natural diamond.

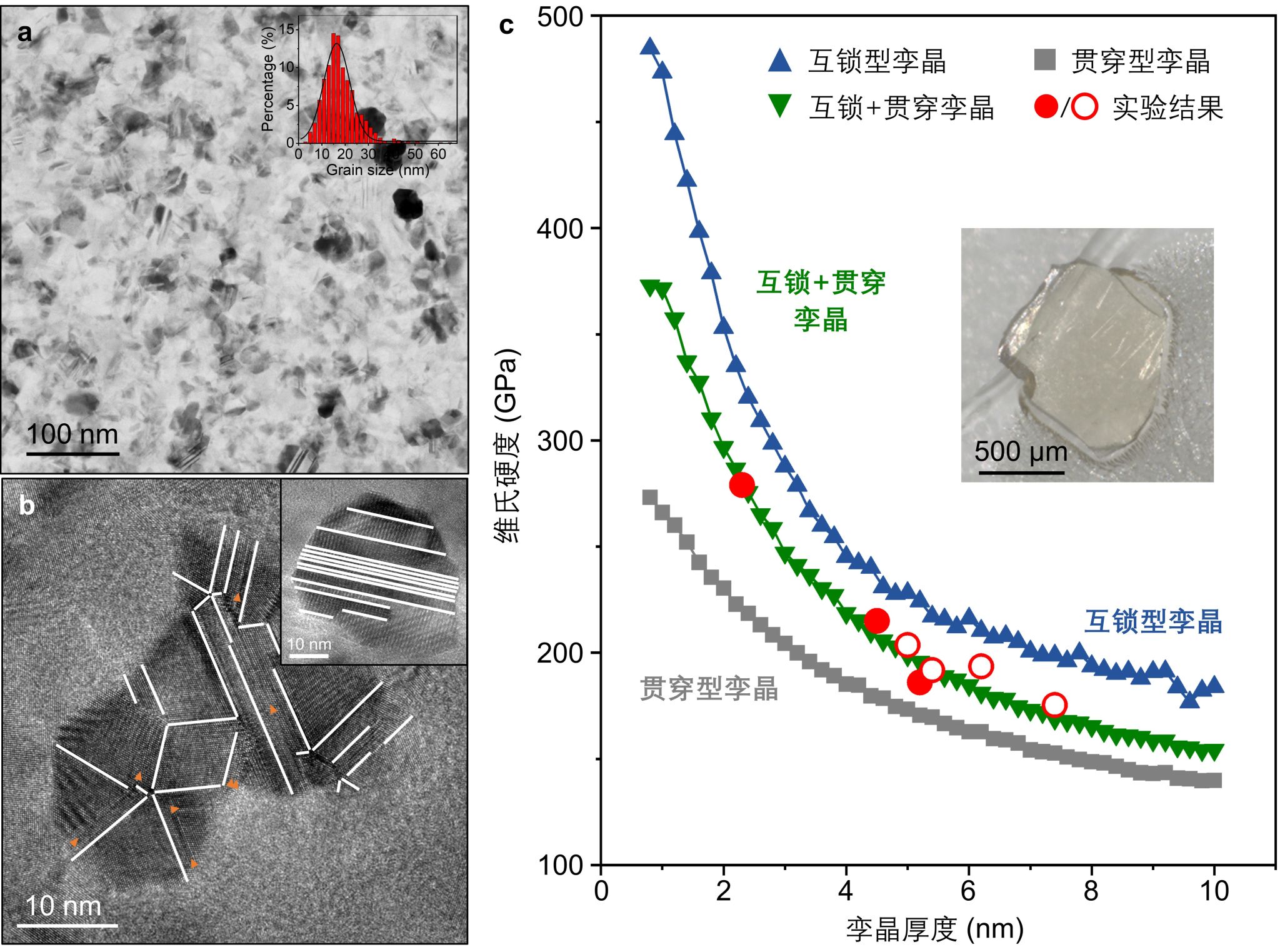

In their latest study, the research team successfully synthesized an ultrafine nanotwinned diamond bulk material with groundbreaking properties. This achievement was made possible by precisely controlling the size of onion-like carbon precursors and inducing high-pressure phase transformations. The resulting material features an average grain size of 18 nm and an average twin thickness of just 2.3 nm, along with a remarkable hardness of 276 GPa. Electron microscopy revealed the presence of both penetrating twins and interlocked twins in the samples, with the interlocked twins being the dominant type. Comparative experiments further confirmed the critical role of this unique structure. Despite achieving similarly fine grains (24 nm), nanocrystalline diamond prepared from diamond powder exhibits a hardness of only 125 GPa due to the absence of a dense interlocked twin structure.

This breakthrough not only sets a new record for hardness but also paves the way for exploring new frontiers in surpassing the hardness limits of covalent materials. By refining and controlling the type of twin structures, the research team has pioneered a novel approach to enhancing material performance, providing crucial guidance for the future developments of superhard materials.

The project is funded by the National Natural Science Foundation of China (52288102, 52325203, 52090020), the National Key Research and Development Program of China (2018YFA0703400, 2023YFA1406200), the Natural Science Foundation of Hebei Province (E2022203109, E2023203256, E2023203126), and other programs. The co-first authors of this study are Ying Pan, Li Baozhong, and Ma Mengdong from YSU, with corresponding authors Tong Ke, Zhao Zhisheng, and Xu Bo. The co-corresponding authors include Pan Yilong from Ningbo University and Tang Guodong from Nanjing University of Science & Technology.

Legend: The microstructure and Vickers hardness of ultrafine nanotwinned diamond. a) The bright-field STEM image shows the sample’s overall microstructure. The inset shows the grain size distribution obtained through statistical analysis, with an average grain size of 18 nm. b) The high-resolution TEM image highlights the characteristic twin structures within the sample: the main image shows predominant interlocked twins, while the inset shows penetrating twins observed in localized areas. c) The figure shows the variation in hardness with twin thickness calculated based on the dislocation model, alongside hardness data obtained in experiments. The inset provides an optical photograph of the ultrafine nanotwinned diamond sample.