A research team led by Academician Tian Yongjun from the State Key Laboratory of Metastable Materials Science and Technology at YSU, in collaboration with Academician Yang Wei’s team from the Center for X-Mechanics at Zhejiang University, has successfully activated deformation twinning-mediated plastic deformation in cubic boron nitride (cBN) and diamond at room temperature for the first time, revealing a novel continuous-transition-mediated deformation twinning mechanism. This achievement not only fills a gap in the study of deformation twinning in extremely hard and brittle covalent crystals but also provides a pivotal scientific basis for the extension of the applicability of classical plasticity theory and the development of a new generation of high-performance materials. The findings, entitled “Activating Deformation Twinning in Cubic Boron Nitride”, were published online in Nature Materials on February 12, 2025.

Deformation twinning is one of the fundamental mechanisms of plastic deformation in materials. In the field of metallic materials, deformation twinning theory is well-established and widely applied to enhance the strength and toughness of materials, as demonstrated in the development of high-performance materials such as TWIP steel and rubber-like metals. However, for extremely hard and brittle covalent crystals such as diamond and cBN, the activation of deformation twinning, its underlying mechanisms, and the improvement of mechanical properties have remained unresolved challenges in materials science. The research teams from YSU and Zhejiang University developed a strategy for activating deformation twinning in covalent crystals based on first-principles calculations and experimental validation. The study found that when compressive load is applied along a specific crystallographic orientation (e.g., <100>), the critical shear stress of cBN significantly decreases, enabling deformation twinning to dominate the plastic deformation process. This strategy is not only applicable to cBN but has also demonstrated universality across a wide range of face-centered cubic covalent crystals, including diamond, silicon carbide (SiC), boron arsenide (BAs), and gallium arsenide (GaAs), thereby establishing a new paradigm for related materials research.

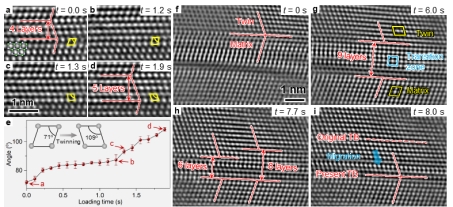

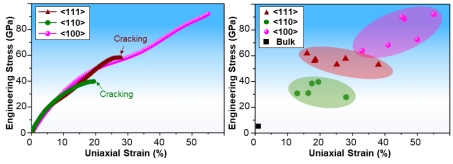

A key breakthrough was the research teams’ self-developed “X-Nano” in-situ transmission electron microscopy (TEM) holder, which enables five-degree-of-freedom manipulation with sub-nanometer precision and is equipped with the world’s hardest nanotwinned diamond indenter. This system enabled the atomic-scale dynamic observation of deformation twinning in cBN for the first time. (Fig. 1). Through experiments, the teams discovered a twinning mechanism — continuous-transition-mediated deformation twinning mechanism — fundamentally different from that in conventional metallic crystals. In conventional metallic materials, deformation twinning occurs via the layer-by-layer slip of partial dislocations, whereas in cBN, the twinning process manifests as a collective transition of all atoms beneath the (111) crystallographic plane (Fig. 2). This mechanism generates a multi-layered atomic “transition zone” that uniformly accommodates large strains, significantly delaying crack initiation. Remarkably, similar phenomena were observed in bulk diamond, indicating the broad applicability of the continuous-transition-mediated deformation mechanism in extremely hard and brittle materials. The study revealed that cBN submicron pillars with activated deformation twinning exhibit extraordinary mechanical properties: a fracture strain of up to 55% and a strength exceeding 92 GPa, which are 55 times and 17 times higher than those of bulk single crystals, respectively, and twice as high as samples deformed via conventional dislocation slip mechanisms (Fig. 3). This leap in performance stems from the synergistic effects of deformation twinning and multiple deformation mechanisms, including the activation of multiple twinning systems and the absorption and obstruction of dislocations by twin boundaries. Deformation twinning not only enables more homogeneous plastic deformation but also significantly enhances the crack resistance of materials through multi-mechanism synergies, breaking new ground for optimizing the properties of extremely hard and brittle materials.

This study extends classical plasticity theory to the realm of covalent crystals for the first time, offering a fresh perspective on material design under extreme conditions. In practical applications, the findings are expected to drive innovations in ultra-hard material processing, high-performance semiconductor devices, and precision mechanical manufacturing. For instance, by controlling deformation twinning, it may be possible to develop next-generation cutting tool materials that possess both high hardness and toughness or improve the reliability of electronic devices under complex stress conditions.

The study was conducted jointly by the State Key Laboratory of Metastable Materials Science and Technology at YSU and the Center for X-Mechanics at Zhejiang University. The co-first authors of the paper are Bu Yeqiang, Su Zhengping, Huang Junquan, and Tong Ke, with Nie Anmin and Wang Hongtao serving as corresponding authors. The project is funded by the National Natural Science Foundation of China (52288102, 52090022, etc.), the Natural Science Foundation of Hebei Province (E2024203054, E2022203109), and other programs.

Figure 1. Five-Degree-of-Freedom TEM Holder with Sub-Nanometer Displacement Precision and Successful Activation of Deformation Twinning in Ultrahard cBN

Figure 2. Atomic-Resolution Dynamic Characterization of Deformation Twinning in Ultrahard cBN

Figure 3. Achievement of Strength and Toughness in cBN via Activated Deformation Twinning