With the support of the National Natural Science Foundation and the National Key R&D Program, Professor Tian Yongjun's team from the State Key Laboratory of Metastable Materials Science and Technology at Yanshan University (YSU), in collaboration with Professor Guo Lin's team from the School of Chemistry at Beihang University, has made significant progress in revealing the room-temperature self-healing behaviour of a fractured nanotwinned diamond composite. This significant discovery has broken through traditional perceptions of diamond materials. The related findings were published online in Nature Materials on September 21, 2023. (You can access the article at the following link: https://www.nature.com/articles/s41563-023-01656-4, Self-healing of fractured diamond).

In 2020, YSU, in collaboration with Beihang University and other partner institutions, jointly proposed an innovative method for toughening diamonds. Through multi-level structural modulation, they successfully synthesized a diamond composite material. This material is assembled from the bottom up and consists of coherently aligned diamond polytypes, intertwined 3C diamond nanotwinned crystals, and interlocking diamond nanocrystals. Through this innovative microstructure design, the material, while maintaining a hardness of 200 GPa, benefits from the synergistic effects of nanotwinned crystal toughening, laminated composite toughening, and phase transformation toughening. As a result, the fracture toughness of the diamond material has been increased to 26.6 MPa × m0.5, approximately five times that of synthetic diamond, surpassing magnesium alloys, and comparable to aluminum alloys. This achievement was published in Nature in 2020 (Nature 2020, 582, 370-374). During the characterization of the fracture toughness of the nanotwinned diamond composite material, researchers observed, for the first time, the phenomenon of crack self-healing within the test samples.

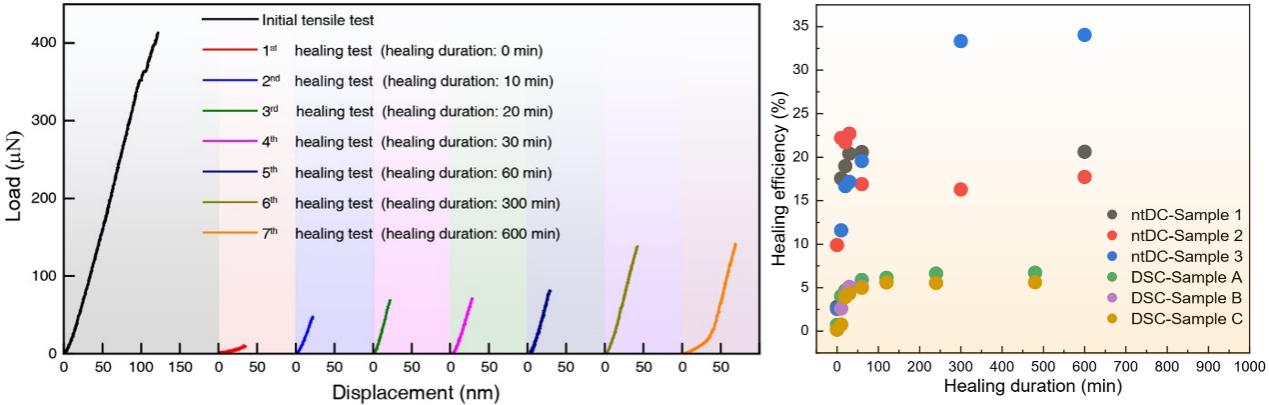

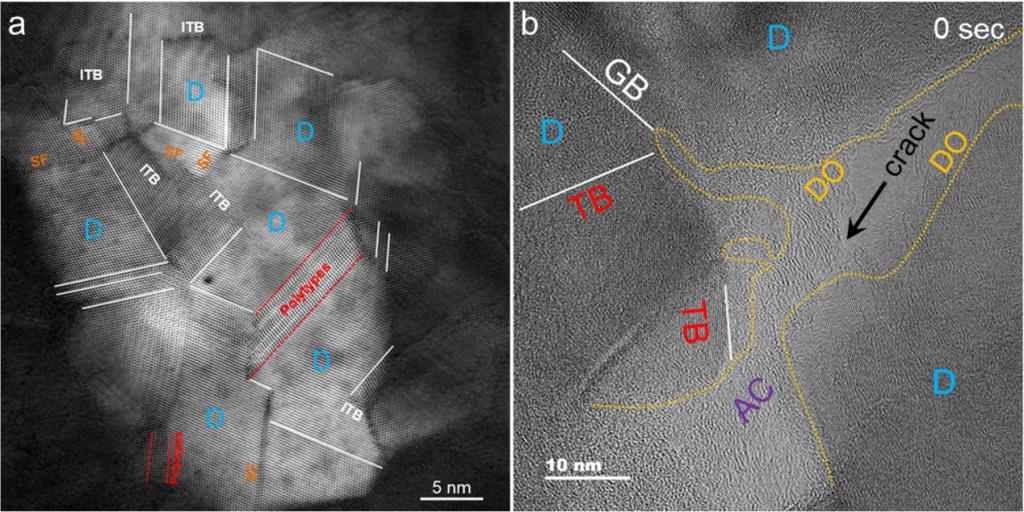

The research teams from YSU and Beihang University conducted in-depth studies on the self-healing behavior of cracks in nanotwinned diamond composite materials. They employed in-situ scanning electron microscopy and transmission electron microscopy mechanical testing methods to systematically characterize the self-healing behavior of nanotwinned diamond composite materials, ranging from mesoscale to microscale and down to atomic scale. Comparative experiments with single-crystal diamonds were also conducted. The research findings indicate that, in the absence of external pressure, nanotwinned diamond composite materials that have completely fractured at room temperature exhibit remarkable crack self-healing capabilities. Their self-healing efficiency is approximately 34%, significantly higher than that of single-crystal diamond, which is 6.7% (Fig.1). Atomic-resolution in-situ observations revealed that nanotwinned composite materials formed an amorphous carbon structure with sp2 and sp3 hybridized carbon atoms on the fractured surfaces (Fig.2). These carbon atoms re-bonded upon contact, thereby achieving the material's self-healing (Fig.3).

This research has paved the way for the design and development of highly durable and fracture-resistant brittle ceramic materials. It also provides valuable guidance for the development and utilization of self-healing materials with strong covalent bonds. Nie Anmin and Tian Yongjun from YSU, along with Yue Yonghai and Guo Lin from Beihang University, are the corresponding authors of this article. (Edited by Yue Ruiyan)

Fig.1. Quantitative Evaluation of Self-Healing Behavior of Fractured ntDC/DSC

Fig.2. Microstructure of Nanotwinned Diamond Composite Materials and the Amorphous Carbon Structure with sp2 and sp3 Hybridized Carbon Atoms on Fractured Surfaces (TEM Image)

Fig.3. Atomic Interaction Forces Transitioning from Repulsion to Attraction Followed by C-C Rebonding