Through cooperation with scholars at home and abroad, a research team led by academician Tian Yongjun from the Center for High Pressure Science, State Key Laboratory of Metastable Materials Science and Technology, Yanshan University, adopted the design strategy of ordered structures with functional units and synthesized the boron nitride ceramic with twisted-layer ordered structures by regulating the solid phase transition from a high-energy metastable state to a low-energy metastable state, which makes a major scientific breakthrough in making bulk ceramics possess plasticity at room temperature. The research achievement, titled Twisted-layer Boron Nitride Ceramic with High Deformability and Strength, was published in the Nature journal [Nature 626, 779–784 (2024)] on February 21, 2024 (link: https://www.nature.com/articles/s41586-024-07036-5). In addition, the research team was invited to release a research briefing in Nature, introducing their work and the story behind [Nature, https://doi.org/10.1038/d41586-024-00443-8 (2024)]. Professor Wu Yiquan from Alfred University in the United States commented, "I am very excited to see the large-scale production and processing of this type of ceramic possible. Besides, graphite experiments have shown that the method improving ceramic properties is not limited to boron nitride but may also be applied to other layered materials."

Compared to metals, ceramics demonstrate excellent characteristics, such as lightweight, high strength, and resistance to high temperature, corrosion, and wear, making them widely applied as structural materials. However, ceramics have very little plasticity at room temperature and may have early brittle fractures with only a small amount of elastic deformation, which can cause catastrophic accidents, constructing their fatal weakness as engineering materials. Since ceramics were invented, people have always dreamed of creating ceramics with plasticity that could produce permanent deformation at room temperature, like metals. Unfortunately, the plastic deformation behavior of ceramics can only be observed at high temperatures or micro-nano scales. It remains a huge scientific challenge to make bulk ceramics possess plasticity at room temperature.

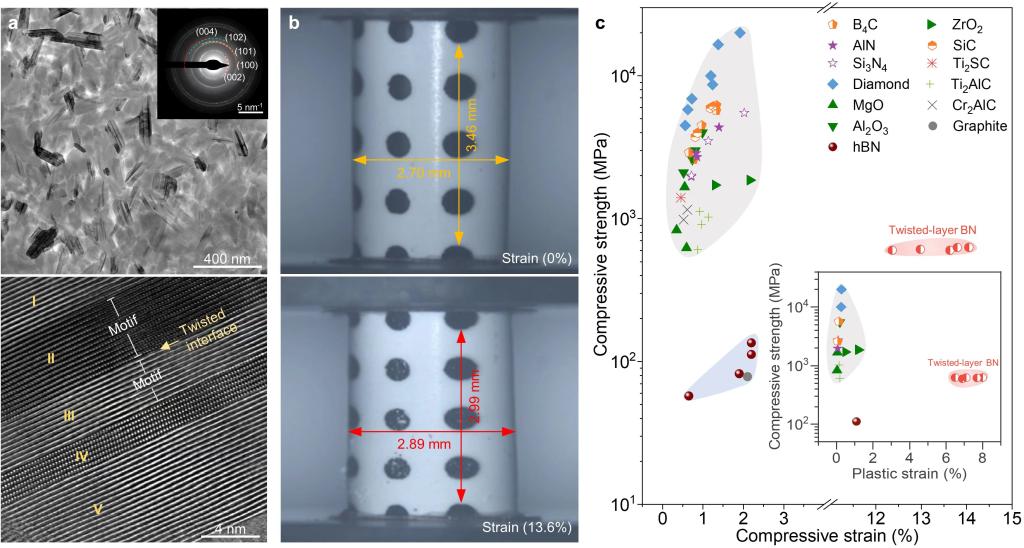

The research team used the structural phase transition during hot-pressing and spark plasma sintering of onion-like boron nitride to synthesize the boron nitride bulk ceramic with a twisted-stacking structure. This ceramic consists of three-dimensional interlocked boron nitride nanoplates in which parallel laminae (several to more than a dozen layers) are stacked with varying twist angles in relative rotations. The twisted-layer boron nitride bulk ceramics have exceptional deformation ability at room temperature. Under the uniaxial compression condition, their compressive strain can reach 14% before fracture, about one order of magnitude higher compared with traditional ceramics. Amazingly, when the compressive strength of this ceramic is six to ten times that of hexagonal boron nitride layered ceramic, its permanent plastic deformation after unloading reaches as high as ~8%, breaking the traditional understanding that it is difficult to simultaneously improve the strength and plasticity of structural materials. On the one hand, the synergy of the improved strength and plasticity is due to the introduction of the twisted ordered structure, which improves the intrinsic deformation ability of the material by two orders of magnitude; on the other hand, the three-dimensional interlocking microstructure interrupts the transmission of kinks, delamination, ripples, dislocations, etc., limiting the deformation to the interior of a single nanoplate, and therefore highlighting the contribution of intrinsic deformation ability while weakening the negative impact of grain boundary.

The twisted-layer boron nitride ceramics demonstrate high strength and plasticity as well as excellent energy absorption capability and fatigue resistance. It is possible to further develop high-performance seals, damping elements, protective armor, and other products. In principle, the material design and synthesis strategy of the research can be extended to other layered material systems, such as graphite and MAX-phase ceramics, enlightening the further development of other ceramics with plasticity.

This work is supported by the National Natural Science Foundation of China (52288102, 91963203, 52325203, 52202071, 52090020, etc.), the National Key R&D Program of China (2018YFA0305900), and the Hebei Natural Science Foundation (E2023203256, E2022203109). The research results have been granted patents for inventions in China, the United States, Japan, and Europe. The co-first authors of the paper are Wu Yingju, Zhang Yang, Wang Xiaoyu, Hu Wentao, and Zhao Song, and the corresponding authors are Zhao Zhisheng and Tian Yongjun.

The images above show the microstructure of twisted-layer boron nitride ceramics and their uniaxial compression properties at room temperature. a. The ceramic consists of three-dimensional interlocking nanoplates, each of which is stacked by layered units with varying twist angles; b. Photos of ceramics before and after deformation at room temperature by uniaxial compression; c. Comparison of deformation ability at room temperature, plasticity, and strength between twisted-layer boron nitride bulk ceramics and traditional bulk ceramics.